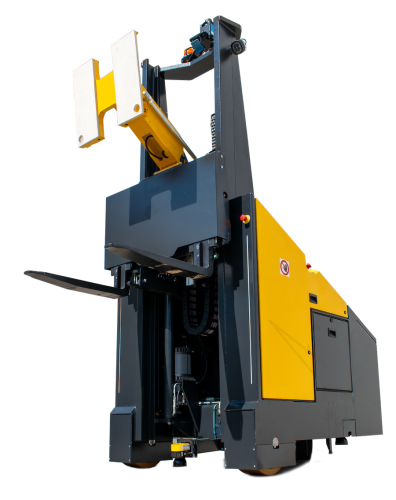

Forklift AGV

The Italcarrelli FC range represents Forklift AGV electric autonomous-guided vehicles designed for lifting and transporting loads placed on pallets and trestles in any type of production or logistics environment.

Main usage sectors:

The Italcarrelli FC Forklift AGV units are equipped with autonomous driving systems that ensure precise movements, safety, and autonomy in handling pallets and trestles. Thanks to the advanced technologies employed, they guarantee high operational efficiency even in very narrow spaces and integrate seamlessly into high-productivity industrial environments.

Technical specifications

Load capacity:

3000 - 5000t

Dimensions:

On request

Power supply:

Batteries, Lithium

Steering systems:

Bidirectional

Drive motors:

AC engines

Navigation technologies:

Optical, inductive, Laser

Command:

Radio controlled

Type of wheels:

Vulkollan tires

Safety devices:

Scan laser, Radar

Industry 4.0 ready:

Yes

Operating environment:

Indoor

Platform height:

Low profile

Need a customized solution?

LOAD

Load Capacity and Safety

With high load capacity and active safety systems, our AGV platforms ensure efficient and maximally safe transport even in environments where personnel are present.

MOTORIZATION

Versatility and Motorization Options

The motorization options include:

- Electric Motors: with lithium batteries, they are an ideal choice for applications requiring energy efficiency and reduced emissions.

ACCESSORIES

Customization and accessories

Optional devices are available, such as signaling lights, load detection sensors, overhead obstacle detection sensors, automatic charging stations (ACS), automated battery exchange stations (BES), and many others.

GENERAL

Overview of Forklift AGV

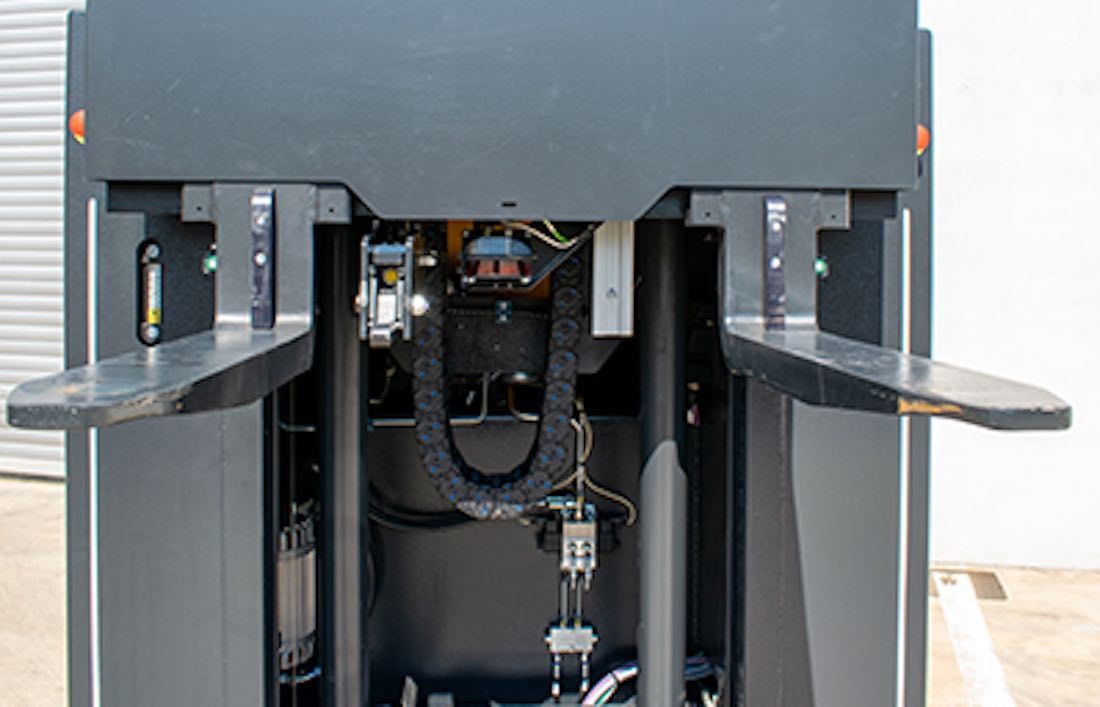

Navigation laser scanner

Constantly checks the machine's position relative to the reflectors to ensure maximum precision in AGV navigation.

Obstacle detection sensor

Scan-laser with programmable areas with slowdown and automatic stop function.

Replaceable batteries

Preparation for automatic battery replacement with BES system.

Dynamic lights

They indicate the driving direction and machine status.

HMI touchscreen

Human-Machine interface with touchscreen

Locking clamp

Hydraulic operation ensures the load on the rack during transportation.

Telescopic forks

Forks positioner and hydraulic swing

AC motor

Brushless to increase reliability and reduce maintenance costs.

Informations and contacts

-9e518e5f.jpeg)