Glass

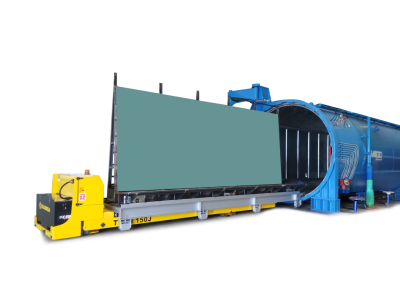

Vehicles that can be used from the end of the line (unloading machines) to the warehouse and from the warehouse to the processing lines or to the shipping area, both for producers and glass processors. The Glass Division is dedicated to the study and design of transport solution best suited to the individual needs of each customer. This is possible thanks to the analysis of the technical-performance requirements, context of use and of course the load, that are considered both in size (DLF or LES, jumbo plates and jumbo XXL plates) and both in the type of storage (glass packages on stillage or in box).

Self-propelled industrial carts for handling and storing industrial glass

Transporters, AGVs and LGVs for large-format glass sheets

We are recognised worldwide as specialists in flat glass handling, offering a complete range of self-propelled carts, self-propelled inloaders transporters, side-loaders, AGVs and industrial transporters designed to meet the production and logistics needs of companies operating in the float glass sector. Through continuous innovation and decades of experience, we develop customised solutions for handling and storing flat glass at every stage of the production cycle, from end-of-line unloading to warehouse operations, from warehouse to processing lines, and finally to the shipping area.

Our self-propelled vehicles are used by float glass production plants, industrial glass manufacturers and glass processors. They are engineered to ensure maximum stability even when dealing with non-standard loads, high manoeuvrability in complex production environments, operator safety, material integrity, automation and seamless integration with advanced logistics systems.

Custom solutions for glass logistics companies

We handle every type of format and storage method: our Glass Division is dedicated to continuously developing customised self-propelled carts for flat-glass handling. Each project is tailored to technical performance requirements, the operating environment and the specific glass format, which may include Lehr End Size, LES (Extra Slim Sheets), Jumbo and XXL Jumbo. All commonly used storage systems in the industry are considered glass packs on A-frames, sheets stored in wooden or metal crates, mixed configurations or fully customised layouts.

Every vehicle is built to ensure precise handling, high load capacity and optimal protection of the glass, even over long internal routes or in storage environments with specific operational constraints.

Case Histories and

projects

Scroll and discover all sectors

-

Glass

LGV Lanutti

Solutions dedicated to Glass

Other application sectors

Scroll and discover all sectors

-

Sectors

Aerospace

-

Sectors

Automotive

-

Sectors

Building materials

-

Sectors

Ceramic

-

Sectors

Coils

-

Sectors

Foundry

-

Sectors

Marble and granite

-

Sectors

Metallurgy

-

Sectors

Nuclear

-

Sectors

Power transformers

-

Sectors

Precast

-

Sectors

Railway

-

Sectors

Renewable energy

-

Sectors

Shipyard

Custom-made machines tailored to Glass sector.