Side-loaders

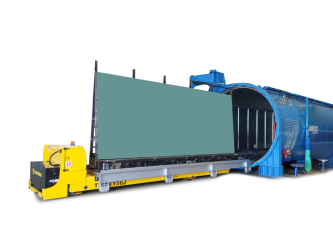

The E4NL series side-loaders are machines for transporting glass packs within float glass plants for flat glass production.

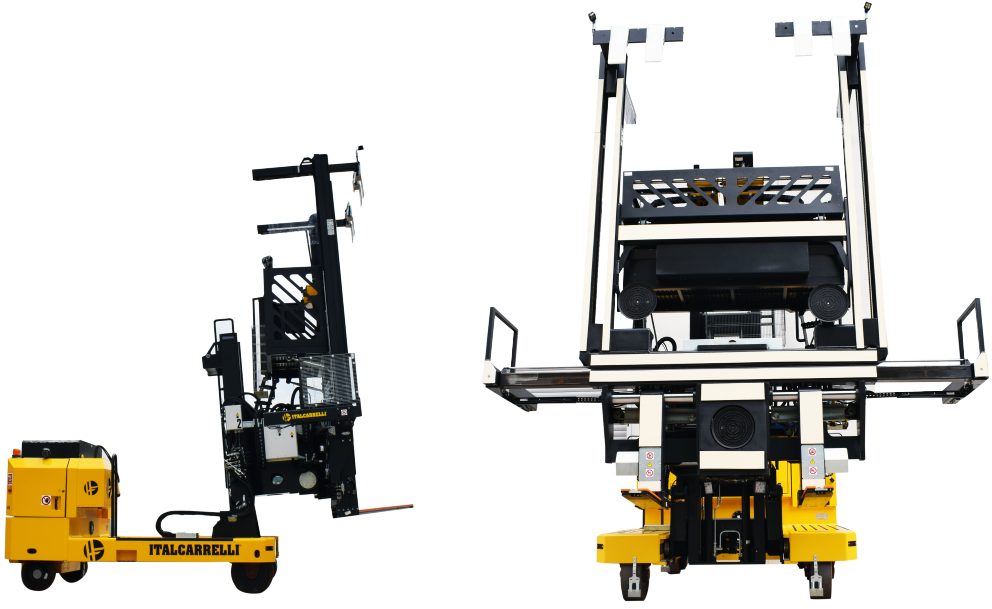

Versions with loading capacity ranging from 3 to 20 tons and more are available, which can transport all glass sizes, from DLF or LES sheets (about 3300 mm long) to jumbo sheets (6000 mm of length and more) and XXL jumbo sheets (over 9000 mm long). Driving positions can be of “standing” type with platform positioned on the upper part of the side-loader to offer greater visibility to the operator or of “seated” type with cabin positioned on the chassis. Control panels consist of a multifunction joystick and a touch screen to allow a simple and fast setting of the forklift.

Technical specifications

Load capacity:

3-20 ton

Dimensions:

DLF-LES, JUMBO, XXL JUMBO

Power supply:

Batteries

Steering systems:

Multidirectional

Drive motors:

AC engines

Navigation technologies:

AGV ready

Command:

Operator on board

Type of wheels:

Vulkollan tires

Safety devices:

Scan laser, AI cameras

Industry 4.0 ready:

Yes

Operating environment:

Indoor

Platform height:

-

Need a customized solution?

LOAD

Load Capacity and Safety

They are equipped with an innovative loading system by means of telescopic forks, which ease glass loading/unloading operations; moreover, thanks to optical and ultrasound sensors, it is possible to perform the alignment and adjustment of the forks according to the number of packs to be transported automatically.

MOTORIZATION

Versatility and Motorization Options

Motorization possibilities include:

- Electric Motors: with lead-acid, pure lead, or lithium batteries are an ideal choice for applications requiring energy efficiency and emission reduction.

ACCESSORI

Customization and accessories

Optional devices are also available, such as video cameras, hydraulic fork positioning devices, suction cups for the clamping of the single sheets and adjustable height-driving cabin to perform the loading of the glass inside trucks, with no need to remove the canopy.

GENERAL

Overview of Side-loaders

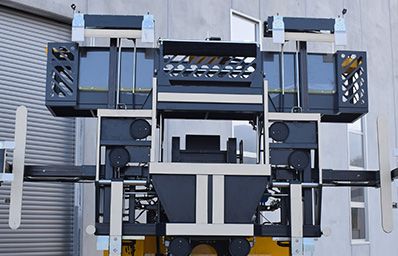

Upper-side clamps

Hydraulically operated according to the size and thickness of the glass pack.

Telescopic frame

Hydraulically adjustable according to the width of the glass to ensure maximum stability.

AC motor

Brushless to increase reliability and reduce maintenance costs.

Vulkollan tires

High load capacity with compact dimensions.

Replaceable batteries

Battery change preparation via crane or forklift.

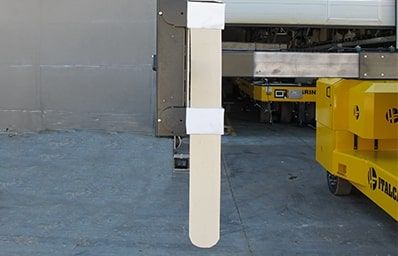

Telescopic forks

Complete with ultrasonic sensors for automatic alignment and optical sensors for automatic positioning.

Suction cups

They allow the handling of a single sheet of glass.

Side control panel

Allow a better view for the operator in side driving.

Cameras on the forks

Allows the operator to monitor the loading/unloading of the glass on the forks from the driver’s seat.

Side clamp cameras

Allows the operator to monitor the loading/unloading of the glass on the forks from the driver’s seat.

Main control panel

Split and adjustable for better ergonomics.

Cameras

Allows the operator to monitor the loading/unloading of the glass on the forks from the driver’s seat.

Informations and contacts

Information, advice, offers.

Use the contact form or call for more information about the products.

Glass handling

Other products in the category

Scroll and discover all products