Case history | Marble and granite

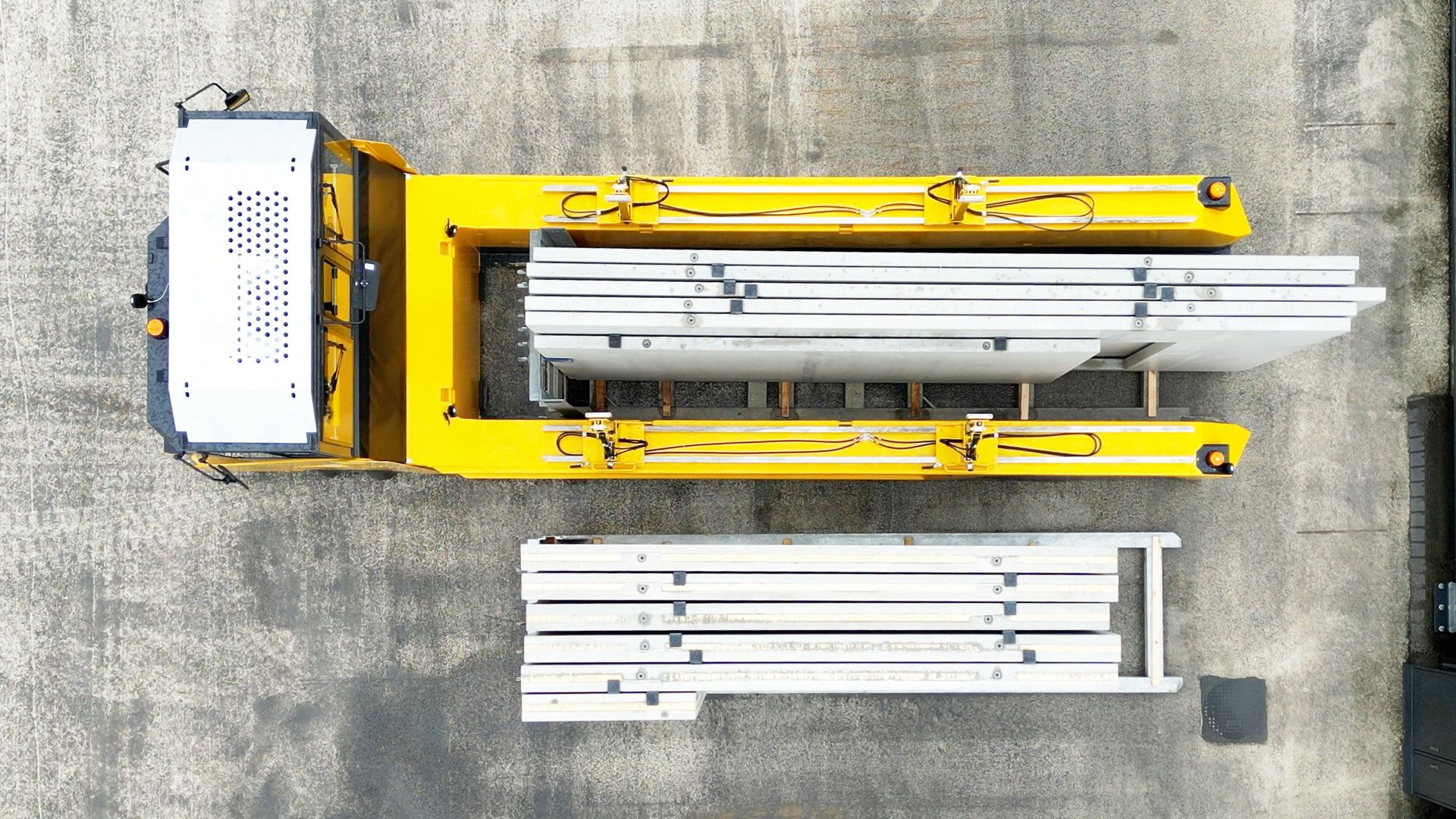

AGV for the Marble Industry

To make all processes more efficient, ITALCARRELLI has developed a series of dedicated self-propelled AGVs for the marble industry.

In modern marble and granite processing plants, the slabs obtained from the block are placed on special stands to be moved between the various processing lines.

Nowadays these lines are completely automated, not only in the processing phases but also in the loading and unloading of the slabs.

Nowadays these lines are completely automated, not only in the processing phases but also in the loading and unloading of the slabs.

These transporters have a capacity of 30,000 kg and a platform height of only 300 mm, which significantly reduces the ground clearance of the stands.

AGV navigation is based on laser technology, entirely developed by ITALCARRELLI, as well as management software that allows the machines to be integrated with ERP and production lines, so that missions are generated automatically without any operator intervention.

These innovative transporters make it possible to benefit from all the advantages of using autonomous guidance in terms of activity planning, warehouse management and digitization, personnel optimization, and increased safety.

All movements, from block cutting, to grinding - resin - polishing - finishing lines, up to the warehouse, are managed by ITALCARRELLI AGVs quickly, efficiently, and completely automatically.

Case Histories and

projects

Scroll and discover all sectors

-

Renewable energy

Greater Efficiency with Tandem Self-Propelled Transporters

-

Foundry

Platform for the Foundry Sector

-

Glass

LGV Lanutti

Informations and contacts