Case history | Foundry

Platform for the Foundry Sector

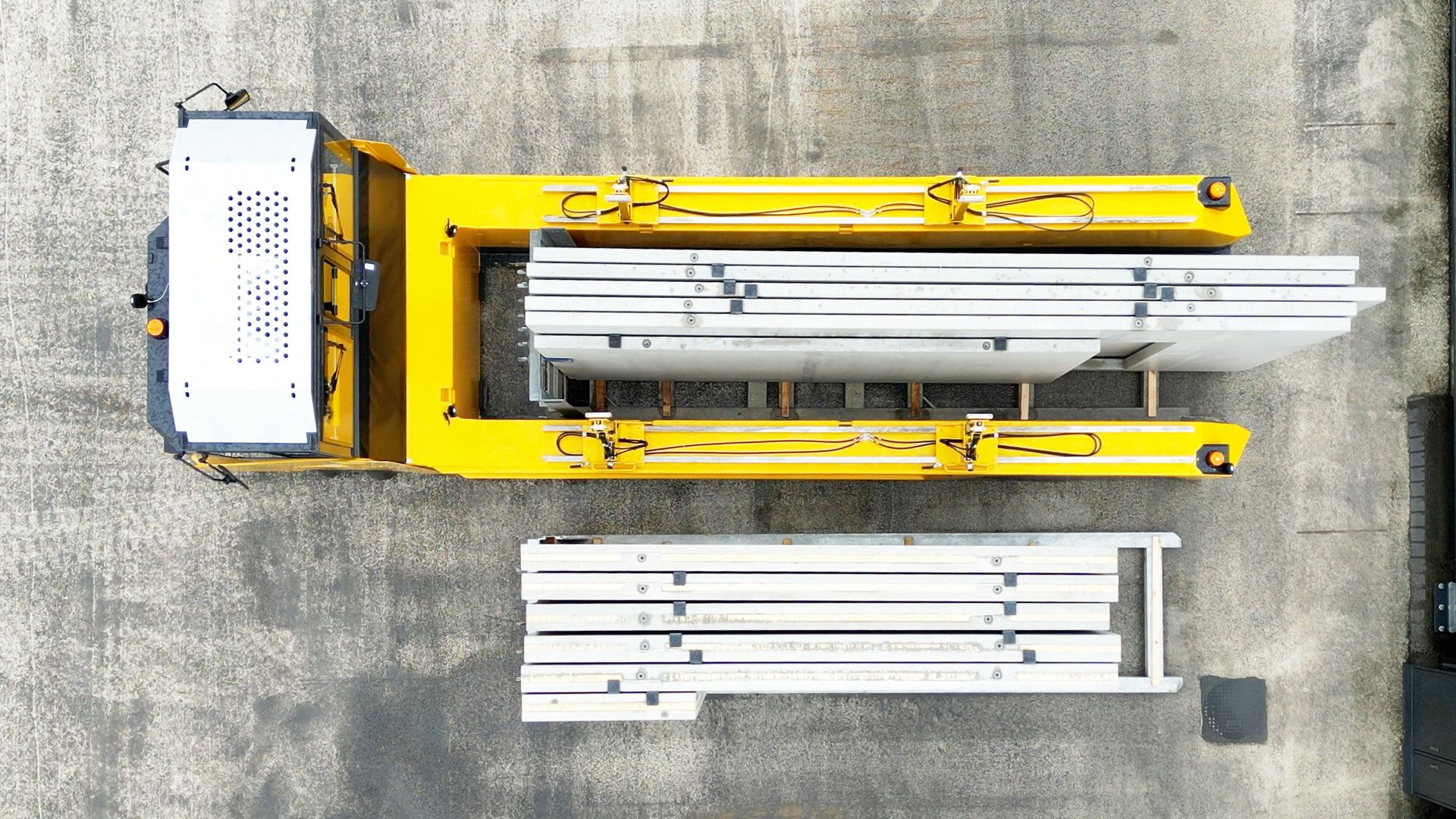

A major foundry producing ballast and counterweights commissioned Italcarrelli to create a high-capacity transporter to move castings from the casting department to the cooling areas.

These molds can be over 4 meters per side and weigh up to 50 tons. After casting, they are placed on special platforms to be transported within the facility.

The movements take place over both short and long distances, and in some areas, the spaces are very tight with poor visibility for the operator.

To meet the customer's needs, ITALCARRELLI developed a customized self-propelled platform, equipped with both an onboard operator station and a remote control.

To ensure maximum comfort for the operator over long distances, the onboard operator station includes a closed cabin with heating and air conditioning and a special ergonomic seat with pneumatic shock absorbers. To guarantee maximum visibility both during loading/unloading operations and during transport, the cabin and operator station can rotate based on the direction of travel.

To ensure maximum comfort for the operator over long distances, the onboard operator station includes a closed cabin with heating and air conditioning and a special ergonomic seat with pneumatic shock absorbers. To guarantee maximum visibility both during loading/unloading operations and during transport, the cabin and operator station can rotate based on the direction of travel.

For short distances, in conditions of limited space and poor visibility, and to position loads precisely, the operator can control the entire transporter from the ground using a special remote control, positioning themselves optimally for maneuvering.

Finally, the multi-directional steering allows the vehicle to move in all directions, ensuring maximum maneuverability in all situations.

Finally, the multi-directional steering allows the vehicle to move in all directions, ensuring maximum maneuverability in all situations.

Scroll and discover

The transporter is equipped with 4 knee axles, developed and produced by ITALCARRELLI, which, in addition to lifting the platform to load the molds, act to compensate for uneven flooring.

Special attention was paid to safety by equipping the machine with radar sensors for obstacle detection and automatic speed reduction based on distance until complete stop.

Special attention was paid to safety by equipping the machine with radar sensors for obstacle detection and automatic speed reduction based on distance until complete stop.

Attention to detail, customer needs, and innovative solutions are the common denominators of all ITALCARRELLI's special transporters.

Case History e

realizzazioni

Scorri e scopri tutti i settori

-

Renewable energy

Greater Efficiency with Tandem Self-Propelled Transporters

-

Marble and granite

AGV for the Marble Industry

-

Glass

LGV Lanutti

Informations and contacts